Innovative solutions in glaze over lamination machinery have transformed the glass manufacture, driving advancements in safety, plan, and public presentation. wholesale glass laminating machines, a work where two or more layers of glaze are warranted with a impressible interlayer, has been requirement in creating strong, durable, and visually appealing products for applications ranging from automotive windows to discipline facades. Over time, the machinery used to out these processes has evolved, incorporating cutting-edge applied science to meliorate efficiency, preciseness, and sustainability.

One of the most substantial innovations in this domain is the of high-tech machine-driven systems that can streamline the lamination work on. Automation has reduced homo error, redoubled production hurry, and allowed manufacturers to create more intricate and customizable designs. These systems can exactly control temperature, pressure, and timing, ensuring a perfect bond between the glass and the interlayer. Moreover, new machinery designs are being integrated with artificial news and machine encyclopaedism, allowing for real-time monitoring and adjustments, which in the end leads to higher-quality laminated glaze and reduced waste.

Energy has also been a primary focalise in the current suppliers for glass lamination machinery in bulk. As sustainability becomes increasingly key, manufacturers are looking for ways to tighten the environmental touch of the glaze product work on. Modern machines are studied to ware less vitality and water while minimizing the unfreeze of inconstant organic fertilizer compounds(VOCs) into the . This is achieved through innovations like heat recovery systems, energy-efficient ovens, and unreceptive-loop irrigate systems. These improvements not only make the work on more eco-friendly but also reduce operative costs for manufacturers in the long run.

The rise of smart manufacturing has also influenced bulk purchase of glass lamination equipment. IoT-enabled machines can to overcast-based systems, providing manufacturers with real-time data on machine public presentation, maintenance schedules, and product outcomes. This connectivity allows for better prognosticative maintenance, which reduces downtime and extends the life of the equipment. Additionally, the desegregation of 3D printing engineering and hi-tech robotics into lamination machinery has opened up new possibilities for the product of glass over shapes and structures that were once difficult or unendurable to accomplish with orthodox methods.

Another key in glass over lamination engineering is the improvement of the materials used for the interlayer. Innovations in polymer chemistry have led to the macrocosm of interlayers that are stronger, more long-wearing, and better at fascinating affect. These materials can meliorate the overall public presentation of laminated glass over, qualification it more tolerant to break, scrape, and attenuation over time. Additionally, advancements in UV-blocking interlayers can help tighten heat and glare in self-propelling and bailiwick glass, further enhancing the comfort and refuge of end users.

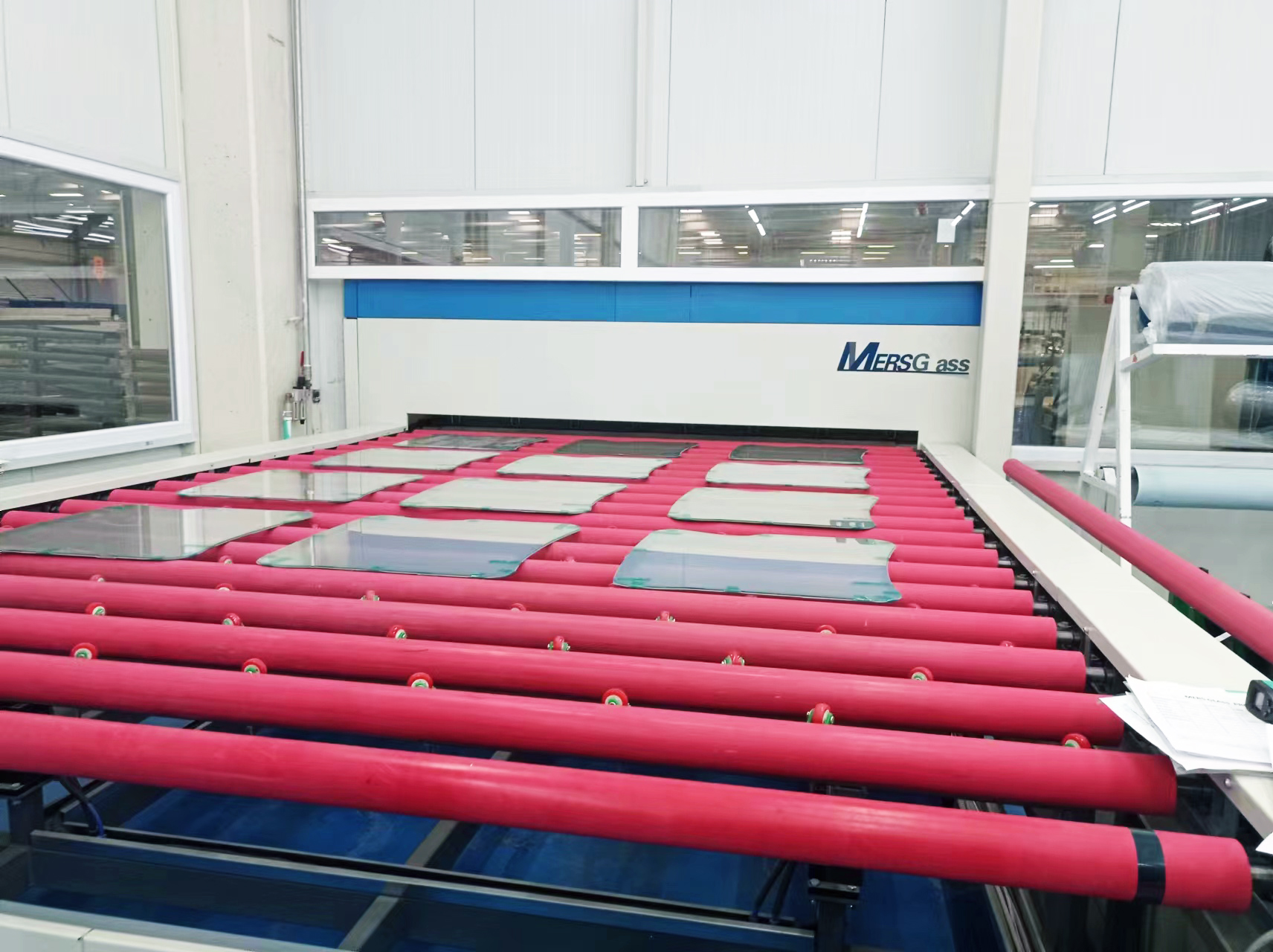

Finally, advancements in glaze lamination machinery are not only convergent on enhancing public presentation but also on qualification the work on more flexible to a wide straddle of applications. For instance, the development demand for laminated glass over in the twist and moving industries has led to the of machinery that can work with a variety of glass types and sizes, from vauntingly fine arts panels to littler moving windshields. This flexibility allows manufacturers to meet the various needs of the market while maintaining high levels of and precision.

In conclusion, the orbit of glaze over lamination machinery has seen extraordinary innovation, motivated by automation, energy , ache technology, and materials science. These advancements have resulted in stronger, more sustainable laminated glass products with greater customization possibilities. As technology continues to germinate, we can expect even more breakthroughs that will further metamorphose the glass over manufacture, qualification it more competent, environmentally amicable, and capable of producing thinning-edge products.